Transportation Technology Center (TTC)

Mission Statement

To provide innovative world class research, development, testing, training, and facilities to ensure safe, secure, reliable, and efficient rail transportation for the Nation.

FRA's Transportation Technology Center (TTC), located in Pueblo, Colorado, celebrated its 50th anniversary in 2021. Since its dedication as the High-Speed Ground Test Center in 1971, TTC has played a vital role in the research, development, and testing of rail infrastructure and equipment — including the Amtrak Acela trainsets prior to revenue service in 2000.

FRA's Transportation Technology Center (TTC), located in Pueblo, Colorado, celebrated its 50th anniversary in 2021. Since its dedication as the High-Speed Ground Test Center in 1971, TTC has played a vital role in the research, development, and testing of rail infrastructure and equipment — including the Amtrak Acela trainsets prior to revenue service in 2000.

ENSCO Inc. currently manages the daily operations of TTC. As TTC's custodian, ENSCO continues TTC's legacy of providing services that align with DOT's vision: advancing rail safety by developing a vibrant, engaging, and modern research facility that drives innovation. More information is at ENSCO's TTC website.

Test Tracks

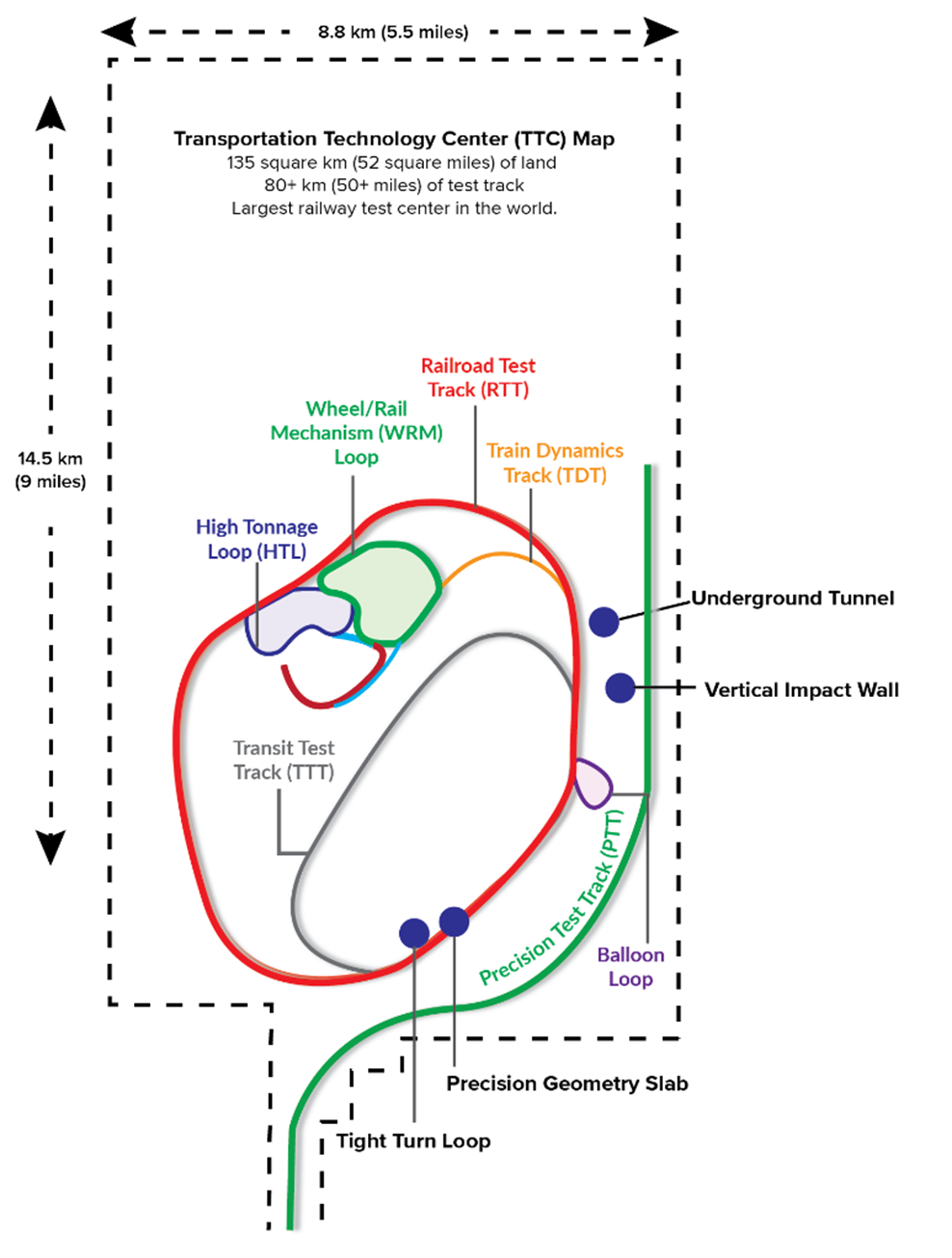

TTC offers over 50 miles of test track at its nearly 52-square-mile facility:

- The High Tonnage Loop (HTL) is a 2.7-mile track used primarily to study long-term wear on train components and rail infrastructure.

- The Railroad Test Track (RTT) is a 13.5-mile loop equipped with a catenary system for testing trains up to 165 mph and the only one of its kind for testing in the U.S.

- The Transit Test Track (TTT) is a 9.1-mile loop designed to simulate urban rail settings and featuring a third rail power system and an integrated tight-turn loop.

- The Precision Test Track (PTT) is a track with purpose-built irregularities that can reproduce the kinds of maximum physical forces (yaw, sway, etc.) a railcar could experience in revenue service.

- The Wheel/Rail Mechanism Loop (WRM) is a 3.5-mile loop designed to test a freight railcar’s ability to safely navigate curves with and without purpose-built track irregularities.

- The High-Speed Adjustable Perturbation Slab Track (HS-APS) is a 500-foot-long tangent section on the RTT designed to assess the capabilities of Track Geometry Measurement Systems (TGMS) and validate vehicle dynamic models used to evaluate the performance and safety of railcars.

TTC Facilities

TTC is at the forefront of rail vehicle safety and dynamics research. Equipment and facilities include:

- Servo-hydraulic stands used for mounting entire railcars

- The Simuloader, which simulates dynamic loads on railcars and locomotives

- The Vibration Test Unit, which characterizes railcars to determine how they respond to dynamic forces

- The Mini-Shaker Unit, which characterizes the suspension systems of railcar bogies

- The Impact Facility, which tests freight and passenger railcars’ crashworthiness and crash energy management to ensure the safest fleet possible

Training and Tenant Organizations at TTC

FRA’s Technical Training Standards Division conducts internal training for safety inspectors and specialists at TTC. Inspectors undergoing training can easily transition from the classroom to field exercises or demonstrations where they can apply recently acquired knowledge. Additionally, co-locating training with RD&T provides other opportunities for cross-functional, hands-on learning about new and emerging rail technologies.

In recent years, the Transportation Security Administration (TSA) has created the Surface Technology Security Training Center located at TTC, which provides training to U.S. Department of Homeland Security inspectors and other Federal, state, and local security partners. Combining test beds and research from different transportation modes can provide government security agencies such as TSA and the U.S. Department of Defense a controlled environment in which to identify and mitigate vulnerabilities, and a one-stop-shop for training activities.

In recent years, the Transportation Security Administration (TSA) has created the Surface Technology Security Training Center located at TTC, which provides training to U.S. Department of Homeland Security inspectors and other Federal, state, and local security partners. Combining test beds and research from different transportation modes can provide government security agencies such as TSA and the U.S. Department of Defense a controlled environment in which to identify and mitigate vulnerabilities, and a one-stop-shop for training activities.

FRA works with Congress and other government agencies to continue to expand the testing capabilities at TTC.